Categories

The Aug. Schwan company

Schwan company stands for straightforward cooperation on a mutual level. As a leading supplier in the card industry, we are a solid part of our customers supply chains. On the bottom line, we provide you with press plates and press pads you need, when you need them. We seek for highest quality, knowing that every damage on the operating resource effects our customer's success. On this page, we would like to briefly introduce ourselves.

Schwan's headquarters and production facility are located in Viersen-Süchteln near the Dutch border in North Rhine-Westphalia. The family business is managed by Richard Grefkes in the third generation.

The company is active in two business areas: PPE and Lamination. Lamination as a global player, PPE within the DACH region.

Both business areas are specializations of Schwan's core business of operating resources. The company employs around 30 people in different departments.

The company is active in two business areas: PPE and Lamination. Lamination as a global player, PPE within the DACH region.

Both business areas are specializations of Schwan's core business of operating resources. The company employs around 30 people in different departments.

With over 40 years of experience as a leading supplier to the card industry, we know what is important to our customers and provide high quality products and services. The goal is to build fair and long-term partnerships with our customers.

„The driving force behind our actions is a fair and long-term partnership with our customers. Their satisfaction with our products as well as our services is our aspiration. We want to support you in your success with our quality, know-how and service.“

Richard Grefkes, CEO

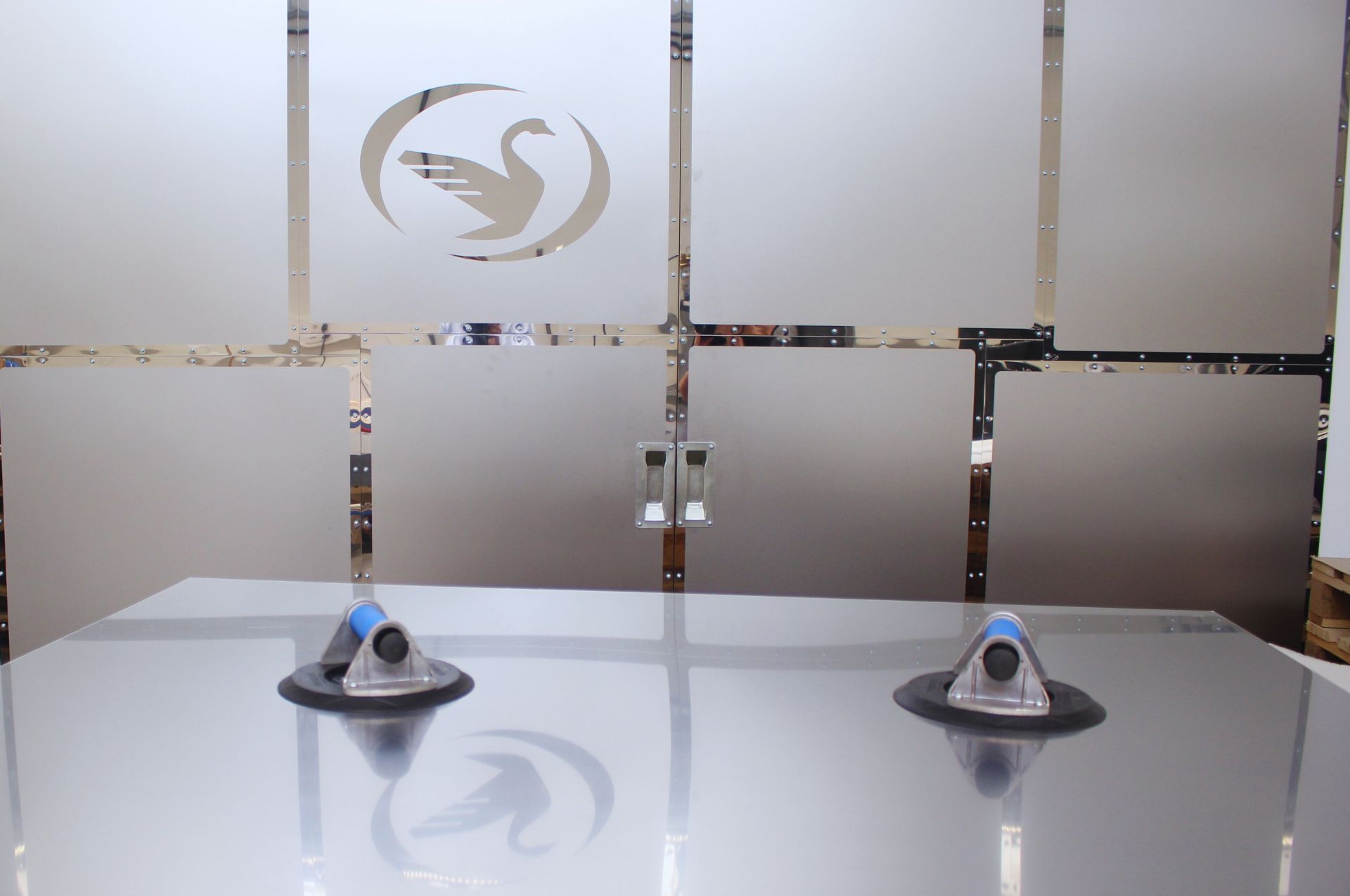

A high quality plate is characterized by a spotless surface. Every scratch, dent or stripe lowers the achievable quality of the cards. This issue applies also for matt finished plates. Indeed, "matt" is a vague declaration. At Schwan we are able to finish both sides of the plate with a defined, consistent Roughness Value (RA).

A high quality plate contains a steady heat conductivity and heat distribution. In addition, the pressure needs to be transported equally and differences in height needs to be compensated within the lamination cassette. A good pad will expand back to its original volume (rebound effect) after the lamination and can be used multiple times. Last but not least, the pad must not bring in contamination.

In the past, many layers of paper were used as a cushion for the lamination process. Modern Press Pads consist of multiple heat-resistant layers with different features. As in consequence, we develop different pads for different purposes.

Plastic card production is a niche market, but a global niche market. On the one hand, connected and dependent to many other industries, we are in a constant learning and development process. On the other hand, cards have become a subtle, but incremental, part of the human life. As in consequence, trends and technical change challenge also the card industry.

A high quality plate contains a steady heat conductivity and heat distribution. In addition, the pressure needs to be transported equally and differences in height needs to be compensated within the lamination cassette. A good pad will expand back to its original volume (rebound effect) after the lamination and can be used multiple times. Last but not least, the pad must not bring in contamination.

In the past, many layers of paper were used as a cushion for the lamination process. Modern Press Pads consist of multiple heat-resistant layers with different features. As in consequence, we develop different pads for different purposes.

Plastic card production is a niche market, but a global niche market. On the one hand, connected and dependent to many other industries, we are in a constant learning and development process. On the other hand, cards have become a subtle, but incremental, part of the human life. As in consequence, trends and technical change challenge also the card industry.

Protection against counterfeiting and sophisticated safety measures can be achieved through surface design and layer structure. Because of these developments, the degree of specialization increases within the market. Further specialization is a challenge Schwan mastered for the last 40 years and continues to master in the future.

The global demand for plastic cards is increasing, forming card producers and suppliers to a global network. Schwans products, service and support are worldwide available. Today, Schwans products are used in more than 40 countries around the globe.

Reliable, smooth and solid - we stand for quality made in Germany!

Get in touch with us! - Your Team Schwan

Whether you are interested in press plates, press pads or accessories for the laminate industry, we are your professional partner.

Use our contact option and get in touch with us today.

Our qualified staff will get back to you as soon as possible!

Contact Us

Back to the top

Back to start page

Use our contact option and get in touch with us today.

Our qualified staff will get back to you as soon as possible!

Contact Us

Back to the top

Back to start page