Categories

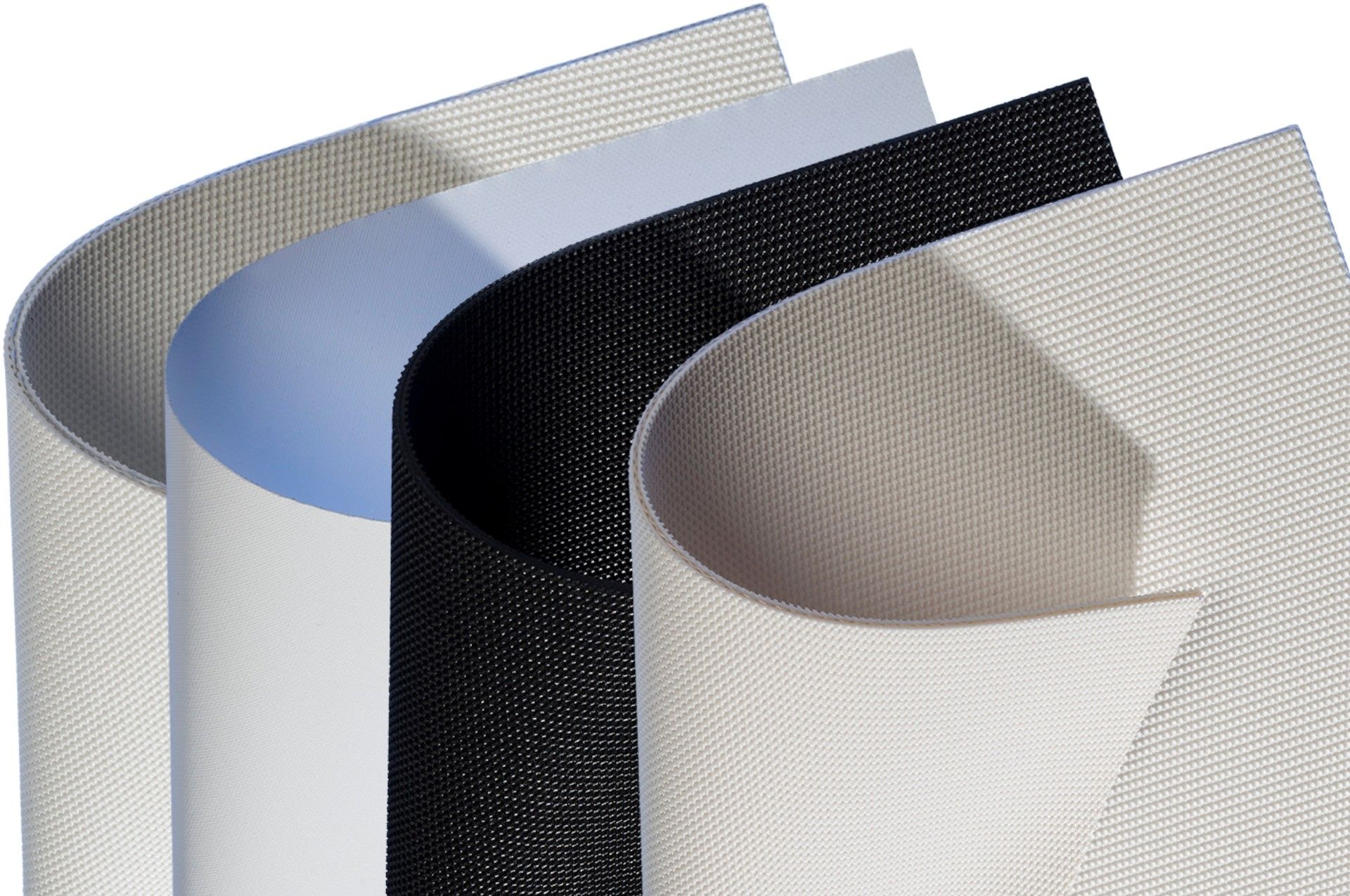

P6200 Series

Our P6200 Series is an all-rounder pad, which can be used for nearly every kind of card. The basic material is silicone rubber surrounding a layer of glass fabric.

Layer: 3-layer press pad

Surface: Top & bottom structured

Operating temperature: 260°C

Available in thickness: 1.9 | 2.3 | 2.7 | 3.3 mm

Application: PVC, PC, ABS, PET(G), etc.

Layer: 3-layer press pad

Surface: Top & bottom structured

Operating temperature: 260°C

Available in thickness: 1.9 | 2.3 | 2.7 | 3.3 mm

Application: PVC, PC, ABS, PET(G), etc.

P6200S Stable Series

Our P6200S Series is an extension of our P6200, which is equipped with an additional double layer of glass fabric for extra stability.

Layer: 5-layer press pad

Surface: Top & bottom structured

Operating temperature: 260°C

Available in thickness: 1.9 | 2.3 | 2.7 mm

Application: PVC, PC, ABS, PET(G), etc.

Layer: 5-layer press pad

Surface: Top & bottom structured

Operating temperature: 260°C

Available in thickness: 1.9 | 2.3 | 2.7 mm

Application: PVC, PC, ABS, PET(G), etc.

P6200AS Antistatic Series

Our P6200AS is a special pad, to reduce static charge within the lamination cassette. The basic material is silicone rubber surrounding a layer of special treated antistatic glass fabric.

Layer: 3-layer press pad

Surface: Top & bottom structured

Operating temperature: 260°C

Available in thickness: 1.9 | 2.3 | 2.7

Application: PVC, PC, ABS, PET(G), etc.

Layer: 3-layer press pad

Surface: Top & bottom structured

Operating temperature: 260°C

Available in thickness: 1.9 | 2.3 | 2.7

Application: PVC, PC, ABS, PET(G), etc.

P7200 Series

Our 7200 is the thinnest pad in the Schwan program. The pad combines rubber and fabric. One side is smooth, the other side is structured.

Layer: 2-layer press pad

Surface: Top structured & bottom smooth

Operating temperature: 200°C

Available in thickness: 0.7 mm

Application: Security cards, ID cards, passports

Layer: 2-layer press pad

Surface: Top structured & bottom smooth

Operating temperature: 200°C

Available in thickness: 0.7 mm

Application: Security cards, ID cards, passports

Black Swan P6200 Series

Our Black Swan P6200 Series is part of our range since 2023/24 and extends the benefits of our P6200 Series with its black color and improved silicone formula.

Layer: 3-layer press pad

Surface: Top & bottom structured

Operating temperature: 260°C

Available in thickness: 1.9 | 2.7 mm

Application: PVC, PC, ABS, PET(G), etc.

Layer: 3-layer press pad

Surface: Top & bottom structured

Operating temperature: 260°C

Available in thickness: 1.9 | 2.7 mm

Application: PVC, PC, ABS, PET(G), etc.

Genius

Our press pad Genius is an innovative pad with PTFE surface. This press pad combines cushion ability and homogeneous heat transfer with absolute no-sticking surfaces.

Layer: 5-layer press pad

Surface: Top & bottom smooth

Operating temperature: 260°C

Available in thickness: Approx. 3.3 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

Layer: 5-layer press pad

Surface: Top & bottom smooth

Operating temperature: 260°C

Available in thickness: Approx. 3.3 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

Ultra

Our press pad Ultra is the pad to choose, when you look for a sealed pad solution. Good cushioning and pressure distribution, as well as a good seal, are the main advantages of this pad.

Layer: 7-layer press pad

Surface: Top & bottom structured aluminum foil

Operating temperature: 260°C

Available in thickness: 3.5 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

Layer: 7-layer press pad

Surface: Top & bottom structured aluminum foil

Operating temperature: 260°C

Available in thickness: 3.5 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

Phoenix

Our Phoenix press pad - the ideal press pad for high-temperature applications. It can withstand an operating temperature of max. 320 °C. This makes it an interesting pad for the PCB industry.

Layer: 3-layer press pad

Surface: Top & bottom structured aluminum foil

Operating temperature: 320°C

Available in thickness: Approx. 2.5 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

Layer: 3-layer press pad

Surface: Top & bottom structured aluminum foil

Operating temperature: 320°C

Available in thickness: Approx. 2.5 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

HTP 8200

Our HTP 8200 press pad is another press pad for high-temperature applications. With its material composition, our pad can withstand temperatures of up to 300°C. It is also quite stiff and antistatic.

Layer: 5-layer press pad

Surface: Woven fiber

Operating temperature: 300°C

Available in thickness: Approx. 3.0 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

Layer: 5-layer press pad

Surface: Woven fiber

Operating temperature: 300°C

Available in thickness: Approx. 3.0 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

Rapid

Our press pad Schwan Rapid is a robust and very fast heat transfer press pad. The maximum operating temperature is at 260 °C.

Material: Silicone elastomers with brass wire warp threads

Surface: Top and bottom structured

Operating temperature: 260°C

Available in thickness: Approx. 2.1 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.

Material: Silicone elastomers with brass wire warp threads

Surface: Top and bottom structured

Operating temperature: 260°C

Available in thickness: Approx. 2.1 mm

Application: PCB, PVC, PC, ABS, PET(G), etc.