Categories

Stainless Steel Plate Card Production

Our high-quality stainless steel plates are one of our bestsellers and used by leading production facilities worldwide. They are perfect for the production of plastic cards such as chip cards and bank cards, and are also perfectly suited for applications like PCB and CCL production.

We only select defect-free surfaces to ensure high-quality production so that your end products meet the highest quality standards. Furthermore, we also check the flatness of the boards to ensure optimum performance in your lamination process.

Each plate is produced on demand, according to the specific requirements of the lamination process. Size, surface and special treatments such as positioning holes are customized by hand here in Viersen, Germany.

We only select defect-free surfaces to ensure high-quality production so that your end products meet the highest quality standards. Furthermore, we also check the flatness of the boards to ensure optimum performance in your lamination process.

Each plate is produced on demand, according to the specific requirements of the lamination process. Size, surface and special treatments such as positioning holes are customized by hand here in Viersen, Germany.

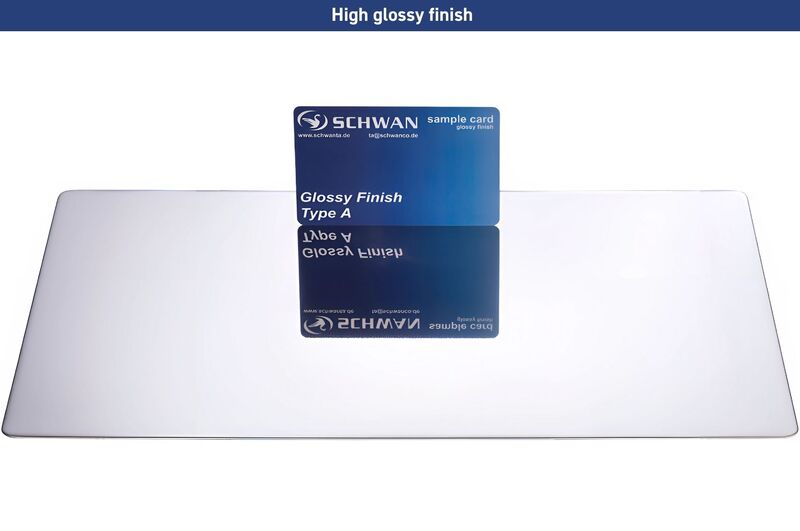

- Master Sheet Finish: High glossy - Both sides of the plates have the same finish and degree of brightness.

- Available Thickness: 0.8 mm | 1 mm

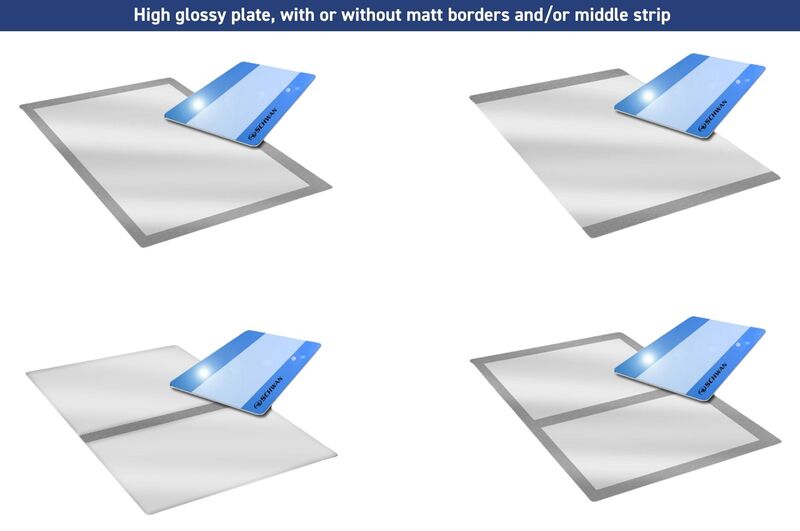

- Finish: High glossy | Matt | High glossy plate, with or without matt borders and/or middle strip

Technical Details

- Material: Stainless steel, Material 1.4016 / AISI SUS 430 BA → non-polished

- Roughness (RA): High glossy plates RA < 0,03 µm, Matt plates RA up to 1,35 µm

- Core Hardness approx. 130–170 HB

- Size tolerance: ± 0.5 mm

- Available thickness: 0.8 mm and 1.00 mm

- All plates are protected on both sides with a strong foil

- Our packaging is conform to ISPM No. 15

- Application: PVC, PC, ABS, PET(G), etc.

Download Specification Data Sheets

Type AStainless Steel Glossy

Types M, G, U S, U M, E, V6, C

Stainless Steel Matt

Type F

Stainless Steel Glossy with or without Matt Borders and/or middle strip

Included Services

Protection Foil: The film is protecting the plates from air particles and other substances.

Smooth Edges & Rounded Corners: During the production process, there is no danger of hurting hands.

Proofed and tested roughness value: Precise brightness is key for your surface? No problem, we check every plate

Reliable and solid packaging: Every order is shipped in a customized wooden box. Therefore, the plates can't move and damage themselves within the packaging

Optional Services

Matt finish: All kinds of roughness are possible, from heavy glossy to heavy matt.

Positioning holes: Due to laser technology, positioning holes can be applied accurate to the hundredth of a millimeter.

Marking: Data-Matrix Codes, serial number, QR-Code can be applied or customized to every scope of application.

Research & Development: We are always open to new ideas and willing to try new set-ups.

Individual shape: Apart from the standard rectangle, all kinds of shapes or cutouts are feasible.